Metalogenia provides after market teeth, keepers, adapters.

Longer wear life and performance

Longer lasting teeth

• More wear life, because as the fitting system is so sturdy, we can make the teeth longer without risking breakage

• Made with Aceros MTG Steels: technologically the most advanced, they afford it greater duration and fewer breakages.

Totally integrated locking system

The pin is totally protected from wear and impact, since it is housed in the adapter.

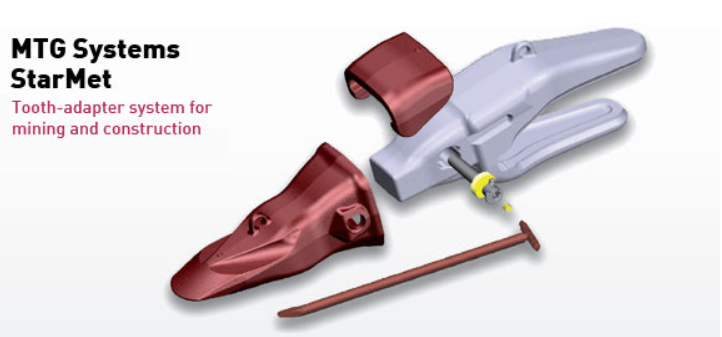

STARMET SYSTEM

MTG Systems StarMet built-in innovative locking solution MTGtwist.

This innovative solution offers:

When changing the teeth:

• Safety: No possibility of impact accidents due to flying metal particles.

• Ease: Tooth changing effort lower than using a hammer.

• Easier to use: One person can change the tooth

When working:

• Safer retention: Tried and tested system offering excellent retention, preventing tooth loss.

• Re-usable pin: The pin is rugged and does not suffer during assembly and disassembly. It can be re-used in most cases.

Lateral locking system for size 15 and from 120 to 500:

1. Easy to extract conical pin.

2. Standard shaped square hole.

3. MTGtwist retainer made from elastomet and polyurethane.

4. MTG plug to prevent the square hole becoming filled with soil, saving time and cleaning when disassembling.

Bilateral locking system for size 20, 30, 40, 50 and 60:

1. Conical pin (can be assembled on both sides of the adapter), for easy installation and removal.

2. Standard shaped square hole.

3. MTGTwist retainer made from elastomet and polyurethane (can be assembled on both sides of the adapter).

4. MTG plug to prevent the square hole becoming filled with soil, saving time and cleaning when disassembling.

EX Design (Extra X) for excavators on loose terrains and particularly abrasive pre-exploded stone quarries that require good penetration.

Applications:

| • | loose and abrasive (gravel) |

I Design (Impact) for excavators and loaders on relatively unabrasive terrains with a high level of impact. Particularly for quarries and applications with large block of stone.

Applications:

- Big rocks loading

- compact and low abrasion (not blasted limestone)

- demolition

P Design (Penetration) for excavators on compact terrains that produce a lot of abrasion and impact and where a high level of penetration is required. Particularly for applications in pre-exploded stone quarries.

Applications:

- compact and abrasive (granite or silicate rock)

- compact and low abrasion (not blasted limestone)

- demolition

RS long profile design for cable loaders in hard applications with a very good resistance, penetration and duration ratio.

Applications:

- Standard

For Rope Shovels applications that require better penetration than teeth RS or RSX but with less impact

Applications:

- Standard

RSX long profile design for cable loaders in hard and highly abrasive applications, with outstanding resistance, penetration and duration ratio.

Applications:

- heavy conditions

U Design (Universal) for excavators on loose terrains with little abrasion and multiple applications. Specific for trench digging and finishings, where maintaining tooth top width constant is very important.

Applications:

- Other Terrains

V Design (Vector) for excavators in very compact terrains.

Applications:

- compact and low abrasion (clay)

W Design (Double Vector) for excavators on extremely compact terrains. The combination of the Vector teeth mounted in the central positions and the Double Vectors mounted in the corners of the bucket provides excellent penetration.

Applications:

- compact and low abrasion (clay)