Lip Systems and Shrouds

MTG LIP SYSTEMS

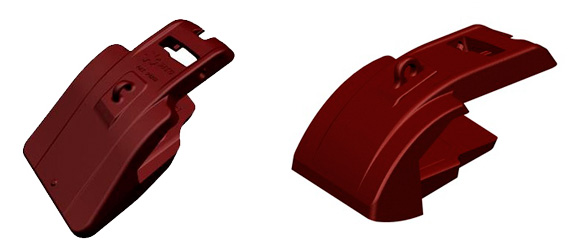

Our range of Promet and ProMet II mechanical lip shrouds for excavators and mining loaders have an improved and optimized design that provides greater bucket protection and ensures better performance with large machines. The Promet and ProMet II range use the MTGtwist hammerless locking system that allow for perfect locking for the most aggressive applications with the utmost safety.

Maximization of the amount of wear material

Maximization of the amount of wear material

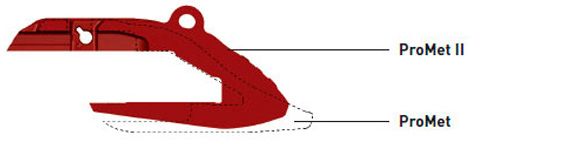

The new design of ProMet II blade shrouds has been optimized based on use in excavators or loaders to offer up to 30% more wear material as compared to the equivalent model of our competitors.

It protects the bucket, increasing its wear life

Reduces the exposure of the blade to impacts and abrasions, increasing the useful life of the bucket.

Longer Wear Life

With the new ProMet II blade shrouds, the front of the shroud contains between 10% and 20% more steel.

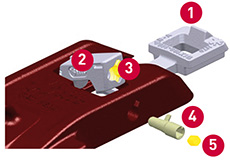

New locking system for easier and faster assembly.

The locking system only requires welding a base for each shroud, making installation easy and quick while reducing machine downtimes.

2. Mechanical locking block.

3. MTGtwist retainer made of Elastomet and polyurethane.

4. MTGtwist hammerless pin.

5. Plug to prevent the square hole becoming filled with soil, saving cleaning time during disassembly.

MTG Systems ProMet incorporates the MTGtwist locking solution which offers:

Safety: No hammer is required preventing accidents when assembling and disassembling.

Comfort: less effort is required than with traditional systems with a hammer.

Easier and faster: changing the elements of the system can be completed much easier and more quickly.

Excellent retention: the pin retention system always keeps the pin in its initial position, completely preventing losing the shrouds.

J-bolt Shrouds

Hensley J-bolt shrouds provide excellent protection for either the leading edge or the wing (cheek) for almost any type of earth moving bucket, and come in multiple styles and range in size to fit wheel loader and excavator buckets.

Features and Benefits

- Mechanically attached to a weld-on base (weldless base available for select dipper lip shrouds)

- Lip shrouds for lips ranging from 2 inch to 9.75 inch thicknesses

- Provides top and bottom lip protection and helps create a flat floor

- Wing shrouds for wings (cheeks) ranging from 2 inch to 5.5 inch thicknesses

- Wing shrouds can be stacked for greater protection

RVS Shrouds

These bolt-on style vertical shrouds provide excellent protection for excavator and wheel loader cheek plates. There is no need for weld-on mounts and your inventory needs are reduced since the shroud will fit the left or right cheek plate. They are also stackable and reversible for even greater protection and wear life.

Features and Benefits

- Bolt-on shroud – no weld-on mount needed

- For 1″ to 2.5″ cheek plates

- Uses standard plow bolt with cone nut

- Reversible for extended wear life

- Stackable for additional protection

Weld-on Lip Shrouds

Without lip shrouds, the leading edge of the bucket is exposed to constant abrasive wear. This can lead to excessive lip wear and may shorten the lifespan of the lip. Hensley has a wide range of universal weld-on lip shrouds available for most construction excavator buckets.

Features and Benefits

- Available for construction and mining class excavators

- Shrouds for 1.5″ lips up to 4.75″ lips

- At least a 300 Brinell for excellent wear resistance

- 7 shroud styles to better match your application

Cast Corner Heel Shrouds

Cast corner heel shrouds will protect your bucket corner edges from aggressive wear that could result in premature bucket failure. These shrouds will help prolong the wear life of your bucket in most construction applications.

Features and Benefits

- Shrouds are cast of low alloy steel for excellent wear resistance

- Multiple styles for excavator and wheel loader buckets

- Easy weld-on installation